We have been involved in the design and maintenance of some of New Zealand’s large scale aquariums and enclosures.

We have been involved in the design and maintenance of some of New Zealand’s large scale aquariums and enclosures.

We have maintained and improved several industrial water treatment plants with clients who are required to meet trade waste consent limits for their facilities along with construction sites who are discharging contaminated construction site run off.

These plants fall into several areas and often a combination:

pH Correction

Facilities which undertake Cleaning in Place (CIP) often have waste water with a pH above or below their discharge consent levels, as such some adjustment is required prior to discharge. These systems often need regular maintenance from instrument maintenance and calibrations through to monitoring of correction chemical levels. As local water authorities can often enforce large fines on facilities discharging outside of their consent levels it is important to ensure that these systems are operating correctly. We have many year of experience with optimising pH correction facilities to reduce chemical and running costs, if you have a pH correction plant or need such a plant then call us to discuss your needs.

Heavy Metal reduction

We have assisted clients over the years build and maintain plants to reduce heavy metal contaminants in their waste water to meet discharge consents. These same problems can also be present with some clients using ground or bore water to supply their facilities. The most common contaminants can include:

Similar to water pH often heavy metal levels can form part of discharge consent conditions or can be a requirement for using the water for processing. Often metal levels can be difficult to reduce however we have experience in several processes that have proven to be cost effective and reliable for our clients.

We have experience in many different areas of water treatment in NZ and also in Australia, in many different areas of industry, if you are considering any of the following processes or have any of the applications listed below then please feel free to contact us.

Ardmore PAC Dosing Plant

|

Process

|

Application

|

|

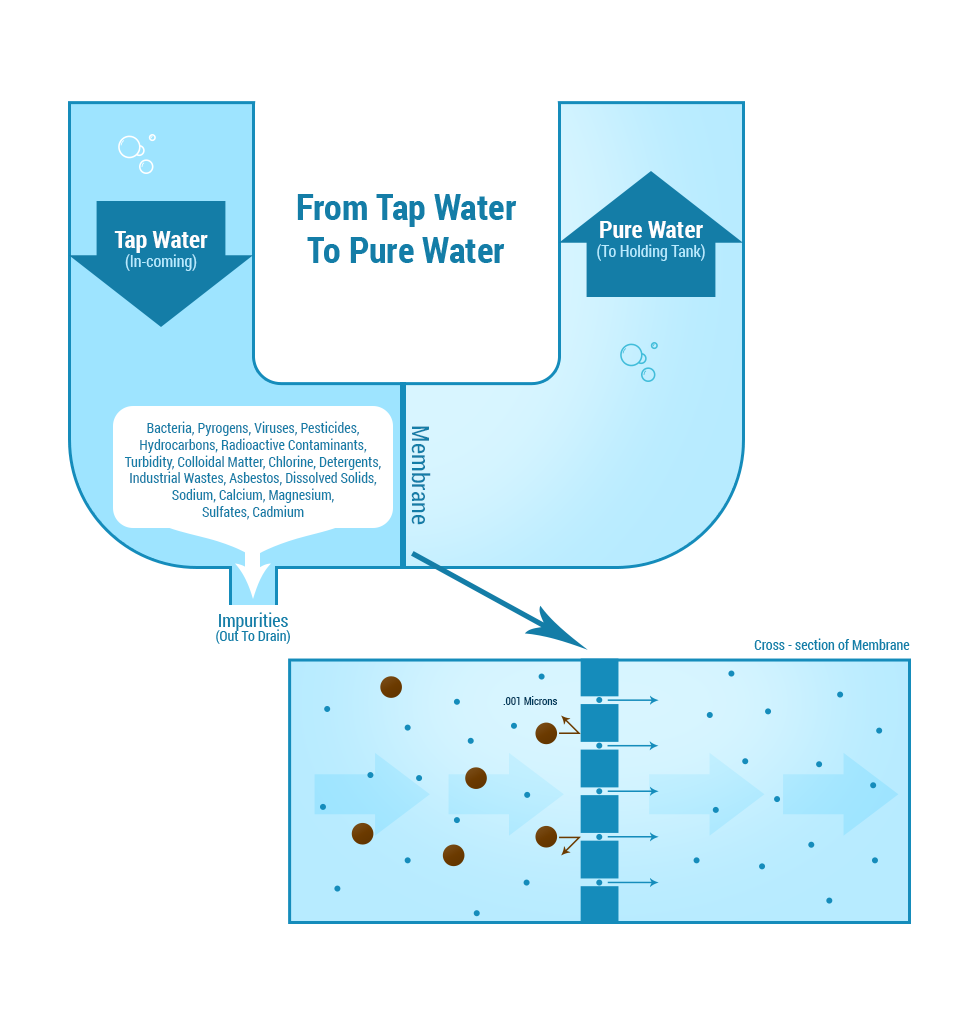

Reverse Osmosis

|

Laboratory water

Hospital instrument washing water

Laser cutter cooling water

Critical Parts washing

|

|

Ion Exchange Demineralisation

|

HP Boiler Feed water

Emissions control water

Industrial processing requiring water with very low contaminant levels

|

|

Softening

|

Hardness reduction

LP Boiler feed water

Low level iron removal

|

|

Multimedia Filtration

|

Greensand – Iron and manganese removal for drinking and industrial water.

Sand – Turbidity reduction in pools, drinking water and industrial water.

|

|

Ozone Injection

|

Aquarium water disinfection

Specialty industrial waste water contaminant oxidation.

|

|

Clarification

|

High volume solids removal such as construction site runoff.

Pond dewatering / backwash waste dewatering

|

|

Ultra Violet Disinfection

|

Drinking water disinfection

Swimming pool water disinfection and contaminant reduction

|

The Auckland Zoo Sealion enclosure and the Wellington Zoo Hospital salt water pool are two facilities our staff have been involved with prior to them being built.

Auckland Zoo Sealion Enclosure

Wellington Zoo Hospital salt water pool

Common uses for RO water in Hospitals and Laboratories.•Water for analyser equipment referencing solutions.

What is Reverse Osmosis (RO) ?

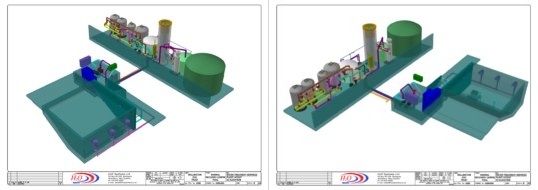

Typically our large scale design projects are completed in autocad in 3D, this reduces the construction time on site and also reduces clashes with other services. As can be seen from some of the examples entire pool complexes can be modelled and checked prior to installation beginning on site.

Including Aquariums, Swimming Pools, Hospitals + Much More.........