PROJECT SUMMARY:

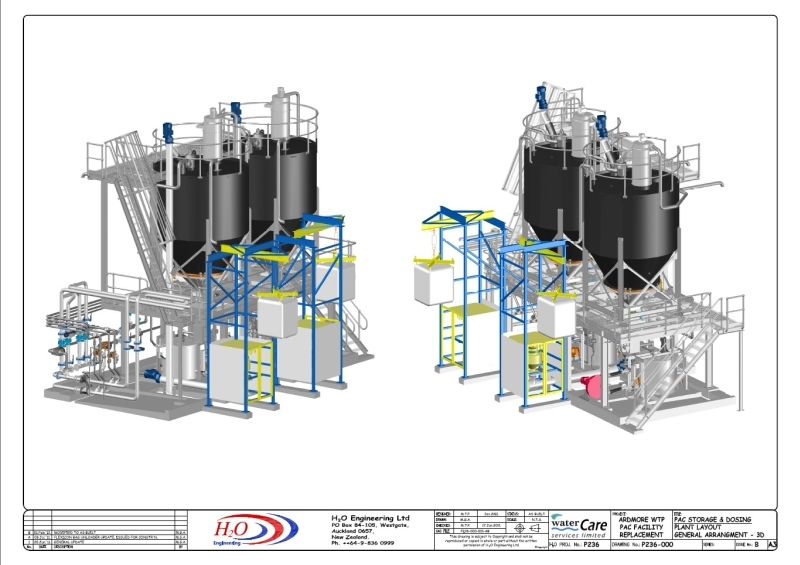

As part of the ongoing improvements to the Ardmore WTP, H2O Engineering where contracted to replace the existing Powdered Activated Carbon (PAC) facility with an industry best practice storage and handling facility.

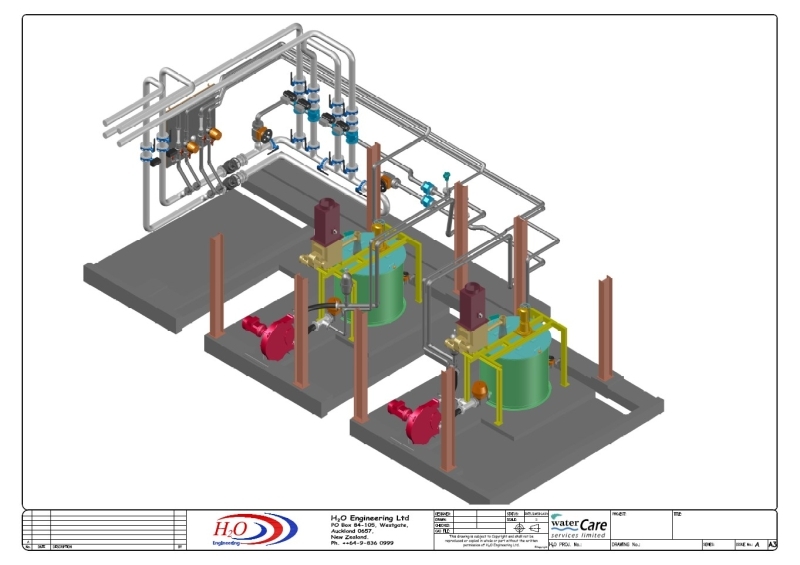

The scope included detailed design, installation and commissioning of the specialist PAC dosing equipment.

CLIENT: Watercare Services Ltd

PROJECT DETAILS:

The unique challenges provided in this project included the need to keep the existing plant operational and the requirement for the new plant to be designed to exceed HSNO Regulation and Hazardous Area Zone electrical requirements for storage and handling of combustible dust.

KEY PARTS OF THE PROJECT WERE:

- Dose rates ranging from 25-480kg/hr of dry powder

- Twin dosing trains each with 15m3 powder storage

- Zone 22 Explosive Dust rating requirements

- Flexicon Bulk Bag Unloaders and WAM Materials Handling equipment incorporated into plant design

- Demolition of redundant equipment

Detailed planning was needed to ensure project targets were met. Working with the clients engineering consultants, Mechanical Technology Ltd., the new plant was available for dosing within six months from H2O’s contract award with only one week without PAC dosing capability.